Currently Empty: $0.00

🛠️ Lean Tools in Automotive Service – Introductory Training Course

Target Audience: Newly graduated automotive engineers working at service centers

Course Duration: [e.g., 1–2 days / 6–10 hours]

Delivery Method: [e.g., Classroom / Online / Blended]

Course Summary:

This course introduces the basic principles of Lean Thinking and how it applies to automotive service centers. Participants will explore the core lean concepts and practical lean tools that help improve efficiency, reduce waste, and enhance customer satisfaction.

Designed for engineers who are new to the field, this training focuses on simple, real-life examples and daily service operations, giving participants the confidence to recognize waste, suggest improvements, and support a lean culture in the workplace.

Key Learning Objectives:

-

Understand the Lean Philosophy and its role in service center performance

-

Identify the 8 types of waste (Muda) in daily service activities

-

Learn how to use common Lean tools like 5S, Standard Work, and Visual Management

-

Apply Root Cause Analysis and Problem Solving Techniques

-

Improve workflow using Value Stream Mapping and Kaizen principles

-

Develop a Lean mindset focused on continuous improvement

Course Modules:

-

Introduction to Lean Thinking

-

The 5 Lean Principles

-

Types of Waste in Automotive Service (TIMWOOD)

-

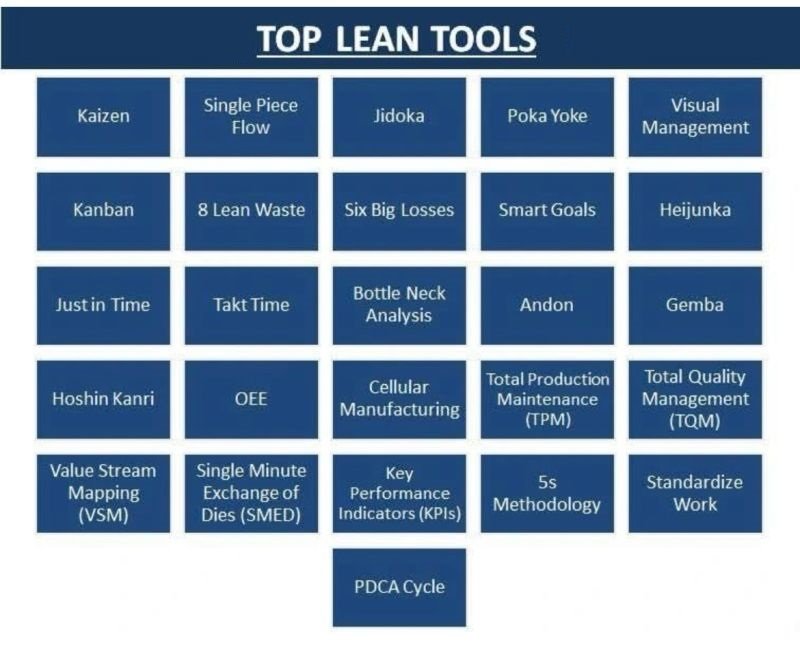

Lean Tools Overview and Application:

-

5S (Sort, Set in order, Shine, Standardize, Sustain)

-

Standard Work

-

Visual Management

-

Kaizen (Continuous Improvement)

-

Root Cause Analysis (5 Whys, Fishbone Diagram)

-

Value Stream Mapping

-

-

Real-Life Applications in Workshops and Front Desk

-

How Lean Tools Improve Customer Satisfaction and Profitability

-

Creating a Lean Culture in the Service Environment

Outcome:

By the end of this course, participants will have a clear understanding of the Lean philosophy and tools, and be capable of identifying inefficiencies and applying lean techniques to optimize workflows, reduce waste, and enhance service quality in their day-to-day roles.

Student Ratings & Reviews

No Review Yet